How does the strengthened cylinder head support its extreme performance while still working stably under high-load turbocharged conditions?

Release Time : 2025-09-09

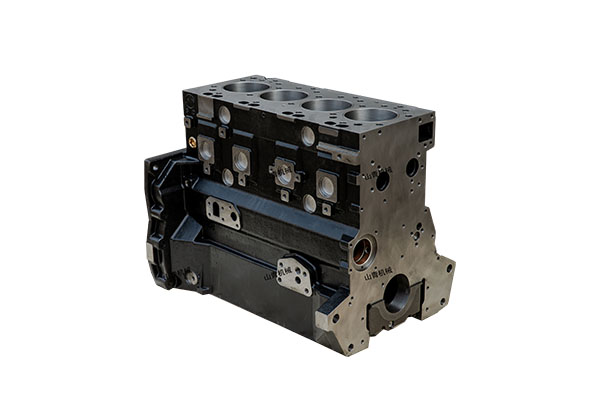

In the operating landscape of modern high-performance engines, the widespread use of turbocharging technology is pushing power output to new heights. However, with rising intake pressures and combustion temperatures, the thermal loads and mechanical stresses within the engine have reached unprecedented levels. Against this backdrop, the cylinder head, serving as the "roof" of the combustion chamber, endures the multiple challenges of high-temperature combustion gases, high-pressure shocks, cooling cycles, and the reciprocating motion of the valvetrain. Conventional cylinder heads are prone to deformation, cracking, and even gasket failure under sustained high loads. However, reinforced cylinder heads remain remarkably stable under extreme operating conditions, supporting the engine's ultimate performance. This is due to the deep synergy of materials, structure, and processes.

The cornerstone of a reinforced cylinder head lies in upgraded materials. It is typically made of high-strength cast aluminum alloy, which not only offers excellent thermal conductivity, enabling rapid transfer of combustion heat to the cooling system, but also possesses exceptional tensile strength and creep resistance. Even under prolonged high-temperature conditions, the material maintains structural stability and resists plastic deformation. Some high-performance cylinder heads are modified with specific elements to further enhance grain density and fatigue resistance, ensuring they remain resilient despite repeated thermal expansion and contraction. This inherent "bone strength" provides the first line of defense against high-pressure shocks.

Optimized structural design imparts enhanced overall rigidity to the cylinder head. The wall thickness around the combustion chamber is precisely calculated to ensure efficient heat dissipation while avoiding localized weaknesses. A more strategic water channel layout forms a continuous cooling zone around key heat-exposed areas, effectively balancing temperature distribution across the cylinder head and preventing thermal stress concentration caused by large temperature differences. Thicker walls between the intake and exhaust ports enhance pressure resistance and prevent microcracking under high boost pressure. The reinforcing ribs and support structure around the bolt holes have also been redesigned to evenly distribute tightening force throughout the cylinder head, ensuring a consistent seal with the cylinder block and preventing loosening due to pressure fluctuations.

Key parts of the valve train have also been reinforced. The valve seats are inlaid with a heat-resistant alloy, ensuring they maintain hardness and dimensional stability even under high-temperature combustion, preventing erosion or sinking that could affect sealing. The valve guides are precision-pressed and made of wear-resistant material, ensuring a stable vertical trajectory during high-speed valve opening and closing, reducing the risk of uneven wear and sticking. These enhanced details not only extend service life but also ensure accurate valve timing, ensuring efficient intake and exhaust efficiency even under high loads.

The reliability of the sealing system is a core priority in strengthening the cylinder head. The mating surface between the cylinder head and the cylinder block is precision-polished to achieve exceptional flatness. Combined with a high-performance multi-layer metal cylinder gasket, this creates a multi-layer sealing barrier. Even during severe pressure fluctuations, it effectively prevents the infiltration of high-pressure combustion chamber gases, coolant, and engine oil. Sealing lips or reinforcement rings are added to the edges of the water and oil passages to prevent leakage caused by minor deformation. This impeccable sealing ensures the engine's sustained and stable power output.

Rigorous manufacturing processes are consistently implemented throughout. From mold casting to heat treatment and CNC machining, every process adheres to stringent standards. Critical dimensions such as combustion chamber volume, bolt hole locations, and water channel openings undergo meticulous testing to ensure precise alignment with the original design. Surface treatment further enhances corrosion and fatigue resistance, making the cylinder head less susceptible to microcracks and oxidation spalling during long-term use.

More importantly, the reinforced cylinder head is not an isolated entity; it is a system engineered to complement the entire engine. Its design fully considers the turbocharger's response characteristics, the cooling system's heat dissipation capabilities, and the fuel injection combustion pattern, ensuring simultaneous thermal management and structural load-bearing while delivering explosive power. This system-wide synergy ensures stable engine operation under high loads, without limiting performance due to local weaknesses.

As the engine roars and power surges, the reinforced cylinder head silently endures the harshest tests. Unassuming, yet with its solid structure, precise craftsmanship, and reliable sealing, it supports every extreme output. In the center of the storm of high temperatures and high pressures, it stands as a calm guardian, a true pioneer of performance.

The cornerstone of a reinforced cylinder head lies in upgraded materials. It is typically made of high-strength cast aluminum alloy, which not only offers excellent thermal conductivity, enabling rapid transfer of combustion heat to the cooling system, but also possesses exceptional tensile strength and creep resistance. Even under prolonged high-temperature conditions, the material maintains structural stability and resists plastic deformation. Some high-performance cylinder heads are modified with specific elements to further enhance grain density and fatigue resistance, ensuring they remain resilient despite repeated thermal expansion and contraction. This inherent "bone strength" provides the first line of defense against high-pressure shocks.

Optimized structural design imparts enhanced overall rigidity to the cylinder head. The wall thickness around the combustion chamber is precisely calculated to ensure efficient heat dissipation while avoiding localized weaknesses. A more strategic water channel layout forms a continuous cooling zone around key heat-exposed areas, effectively balancing temperature distribution across the cylinder head and preventing thermal stress concentration caused by large temperature differences. Thicker walls between the intake and exhaust ports enhance pressure resistance and prevent microcracking under high boost pressure. The reinforcing ribs and support structure around the bolt holes have also been redesigned to evenly distribute tightening force throughout the cylinder head, ensuring a consistent seal with the cylinder block and preventing loosening due to pressure fluctuations.

Key parts of the valve train have also been reinforced. The valve seats are inlaid with a heat-resistant alloy, ensuring they maintain hardness and dimensional stability even under high-temperature combustion, preventing erosion or sinking that could affect sealing. The valve guides are precision-pressed and made of wear-resistant material, ensuring a stable vertical trajectory during high-speed valve opening and closing, reducing the risk of uneven wear and sticking. These enhanced details not only extend service life but also ensure accurate valve timing, ensuring efficient intake and exhaust efficiency even under high loads.

The reliability of the sealing system is a core priority in strengthening the cylinder head. The mating surface between the cylinder head and the cylinder block is precision-polished to achieve exceptional flatness. Combined with a high-performance multi-layer metal cylinder gasket, this creates a multi-layer sealing barrier. Even during severe pressure fluctuations, it effectively prevents the infiltration of high-pressure combustion chamber gases, coolant, and engine oil. Sealing lips or reinforcement rings are added to the edges of the water and oil passages to prevent leakage caused by minor deformation. This impeccable sealing ensures the engine's sustained and stable power output.

Rigorous manufacturing processes are consistently implemented throughout. From mold casting to heat treatment and CNC machining, every process adheres to stringent standards. Critical dimensions such as combustion chamber volume, bolt hole locations, and water channel openings undergo meticulous testing to ensure precise alignment with the original design. Surface treatment further enhances corrosion and fatigue resistance, making the cylinder head less susceptible to microcracks and oxidation spalling during long-term use.

More importantly, the reinforced cylinder head is not an isolated entity; it is a system engineered to complement the entire engine. Its design fully considers the turbocharger's response characteristics, the cooling system's heat dissipation capabilities, and the fuel injection combustion pattern, ensuring simultaneous thermal management and structural load-bearing while delivering explosive power. This system-wide synergy ensures stable engine operation under high loads, without limiting performance due to local weaknesses.

As the engine roars and power surges, the reinforced cylinder head silently endures the harshest tests. Unassuming, yet with its solid structure, precise craftsmanship, and reliable sealing, it supports every extreme output. In the center of the storm of high temperatures and high pressures, it stands as a calm guardian, a true pioneer of performance.