How does the honing pattern on the inner surface of cylinder blocks simultaneously achieve aesthetic appeal, oil retention, lubrication, and reduced piston ring wear?

Release Time : 2025-08-26

Deep in the heart of modern power machinery, cylinder blocks, with their silent yet majestic presence, carry the roar of combustion and the rhythm of its reciprocating motion. They are not only the core structural foundation of the engine, but also the crystallization of the fusion of engineering aesthetics and materials science. They transform the explosive force of high temperature and high pressure into smoothly output mechanical energy, embodying the power and precision of industrial civilization with every reciprocating piston movement.

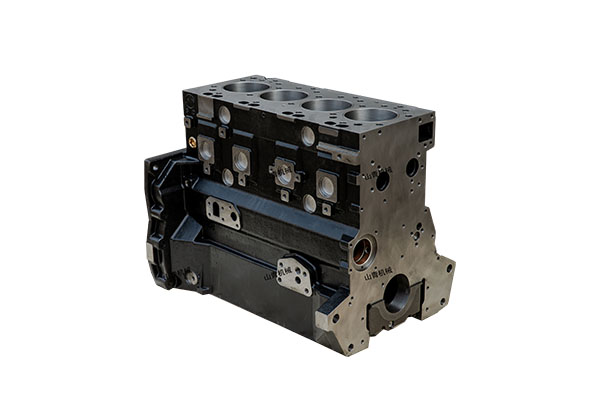

Upon first sight of cylinder blocks, their beauty stems from a "symbiosis of ruggedness and subtlety." Their overall contours are thick and solid, crafted from precision castings of high-strength cast iron or aluminum alloy. The outer walls feature strong lines, and the reinforcing ribs and support structures are arranged in an orderly, skeletal pattern, exuding a quintessential sense of mechanical strength. Complex internal and external features, such as cooling channels, lubrication lines, bolt holes, and main bearing seats, are precision-machined to achieve an exceptionally smooth surface finish. The cylinder inner walls, in particular, are honed to create a delicate crosshatch pattern reminiscent of natural rock formations, both aesthetically pleasing and providing lubrication. The intake and exhaust ducts are smooth and fluid, optimized using CFD (computational fluid dynamics) to achieve natural cross-sectional variations and reduce airflow resistance. Whether in the symmetrical V-type six-cylinder layout or the linear arrangement of the inline four-cylinder, the hole distribution and overall structure demonstrate a rigorous geometric order. Surface treatment is meticulously crafted—cast iron parts are often phosphated or shot-peened, while aluminum alloy bodies are anodized or coated for corrosion resistance and wear resistance, while also imparting a sophisticated industrial aesthetic. This appearance is both a direct reflection of functional requirements and a silent statement of manufacturing precision.

The core innovation lies in the deep integration of "integrated structure" and "thermal-mechanical-fluid synergistic optimization." Modern cylinder blocks are no longer simply a collection of cylinder bores; they are complex integrated systems, including cooling, lubrication, intake and exhaust passages, crankshaft support, and accessory mounting platforms. A water jacket surrounds each cylinder, ensuring even heat dissipation and preventing local overheating. A network of main and branch oil passages provides reliable lubrication for the crankshaft, connecting rod, and camshaft. Precision-machined main bearings ensure concentricity and stability in crankshaft rotation. Cast iron cylinder blocks offer high strength, excellent wear resistance, and low cost, making them widely used in commercial vehicles and industrial engines. Aluminum alloy cylinder blocks significantly reduce weight and increase power density. Combined with cast iron cylinder liners or plasma spraying to address wear issues, they have become the mainstream choice for high-performance passenger vehicles. This evolution in materials and structures represents the culmination of a strategic balance between lightweighting and high performance.

From a performance perspective, their design directly determines engine efficiency, lifespan, and emissions. The honed mesh pattern on the cylinder's inner wall is not only aesthetically pleasing but also effectively stores lubricant and reduces piston ring wear. The optimized intake and exhaust port design improves charging efficiency and enhances combustion. The reinforced ribs and box-shaped structure effectively suppress vibration and deformation caused by combustion pressure and mechanical loads, ensuring long-term operational reliability. For turbocharged engines, cylinder blocks must withstand even higher burst pressures, so their wall thickness, bolt preload, and material strength have been recalculated and verified. Precise machining tolerances (micrometer level) ensure a perfect fit between components, preventing leaks and abnormal noise.

Even more commendable is their role in smart manufacturing. Modern cylinder block production utilizes automated casting, CNC machining centers, and in-line testing technology to ensure that every product meets stringent standards. Their structural design also increasingly prioritizes manufacturability and assembly, facilitating automated production lines.

Cylinder blocks are the "silent foundation" of the powertrain. Their massive body holds the whirlwind of combustion, while their precise interior channels the flow of energy. With every piston stroke and crankshaft revolution, it silently proves that true power lies not in superficial appearances but in the wisdom of its internal structure and its absolute control over extreme operating conditions. It's more than just a component; it's a masterpiece of engineering that harnesses energy and drives the world.

Upon first sight of cylinder blocks, their beauty stems from a "symbiosis of ruggedness and subtlety." Their overall contours are thick and solid, crafted from precision castings of high-strength cast iron or aluminum alloy. The outer walls feature strong lines, and the reinforcing ribs and support structures are arranged in an orderly, skeletal pattern, exuding a quintessential sense of mechanical strength. Complex internal and external features, such as cooling channels, lubrication lines, bolt holes, and main bearing seats, are precision-machined to achieve an exceptionally smooth surface finish. The cylinder inner walls, in particular, are honed to create a delicate crosshatch pattern reminiscent of natural rock formations, both aesthetically pleasing and providing lubrication. The intake and exhaust ducts are smooth and fluid, optimized using CFD (computational fluid dynamics) to achieve natural cross-sectional variations and reduce airflow resistance. Whether in the symmetrical V-type six-cylinder layout or the linear arrangement of the inline four-cylinder, the hole distribution and overall structure demonstrate a rigorous geometric order. Surface treatment is meticulously crafted—cast iron parts are often phosphated or shot-peened, while aluminum alloy bodies are anodized or coated for corrosion resistance and wear resistance, while also imparting a sophisticated industrial aesthetic. This appearance is both a direct reflection of functional requirements and a silent statement of manufacturing precision.

The core innovation lies in the deep integration of "integrated structure" and "thermal-mechanical-fluid synergistic optimization." Modern cylinder blocks are no longer simply a collection of cylinder bores; they are complex integrated systems, including cooling, lubrication, intake and exhaust passages, crankshaft support, and accessory mounting platforms. A water jacket surrounds each cylinder, ensuring even heat dissipation and preventing local overheating. A network of main and branch oil passages provides reliable lubrication for the crankshaft, connecting rod, and camshaft. Precision-machined main bearings ensure concentricity and stability in crankshaft rotation. Cast iron cylinder blocks offer high strength, excellent wear resistance, and low cost, making them widely used in commercial vehicles and industrial engines. Aluminum alloy cylinder blocks significantly reduce weight and increase power density. Combined with cast iron cylinder liners or plasma spraying to address wear issues, they have become the mainstream choice for high-performance passenger vehicles. This evolution in materials and structures represents the culmination of a strategic balance between lightweighting and high performance.

From a performance perspective, their design directly determines engine efficiency, lifespan, and emissions. The honed mesh pattern on the cylinder's inner wall is not only aesthetically pleasing but also effectively stores lubricant and reduces piston ring wear. The optimized intake and exhaust port design improves charging efficiency and enhances combustion. The reinforced ribs and box-shaped structure effectively suppress vibration and deformation caused by combustion pressure and mechanical loads, ensuring long-term operational reliability. For turbocharged engines, cylinder blocks must withstand even higher burst pressures, so their wall thickness, bolt preload, and material strength have been recalculated and verified. Precise machining tolerances (micrometer level) ensure a perfect fit between components, preventing leaks and abnormal noise.

Even more commendable is their role in smart manufacturing. Modern cylinder block production utilizes automated casting, CNC machining centers, and in-line testing technology to ensure that every product meets stringent standards. Their structural design also increasingly prioritizes manufacturability and assembly, facilitating automated production lines.

Cylinder blocks are the "silent foundation" of the powertrain. Their massive body holds the whirlwind of combustion, while their precise interior channels the flow of energy. With every piston stroke and crankshaft revolution, it silently proves that true power lies not in superficial appearances but in the wisdom of its internal structure and its absolute control over extreme operating conditions. It's more than just a component; it's a masterpiece of engineering that harnesses energy and drives the world.