Can the integrated water channel design of the cylinder head optimize cooling efficiency and reduce the formation of engine hot spots?

Release Time : 2025-09-23

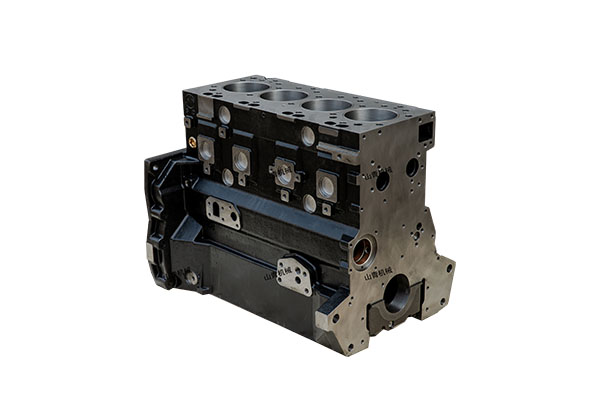

In modern internal combustion engine technology, the cylinder head, as one of the most core components, performs multiple functions, including sealing the combustion chamber, guiding intake and exhaust, housing the valvetrain, and conducting high-temperature heat. As engines continue to evolve towards higher power density, higher thermal efficiency, and lower emissions, thermal management issues are becoming increasingly prominent. Cylinder heads, in particular, are prone to localized overheating under prolonged high-temperature and high-pressure environments, forming "hot spots" that can lead to serious failures such as knock, cylinder head deformation, coolant boiling, and even cracks. To address this challenge, modern cylinder heads generally adopt an integrated water channel design. Through the strategic layout of coolant flow channels, this significantly improves cooling efficiency and effectively prevents the formation of hot spots, becoming a key technology for ensuring engine reliability and performance.

1. Limitations of Traditional Cooling Design

In early engine designs, cylinder head cooling channels were often simply drilled or cast, resulting in a crude layout, uneven coolant flow paths, and insufficient flow rate control. Especially in high-temperature areas such as those around the combustion chamber, exhaust valve seats, and spark plugs, the complex structure and wide variations in wall thickness make it difficult for coolant to adequately cover them. This leads to heat accumulation and the formation of localized high-temperature zones. This uneven cooling not only reduces the fatigue life of the material but can also cause cylinder head warping, compromise the seal between the cylinder block and head, and cause serious failures such as "head gasket blowout."

2. Core Advantages of Integrated Water Channel Design

Integrated water channel design involves embedding coolant channels three-dimensionally into the cylinder head structure using precision molds during the casting process. This creates a complex network of flow channels that surround the combustion chamber, penetrate the valve seats, and proximate the exhaust ports. This design goes beyond simple "through-holes" to create a highly efficient cooling system optimized through CFD simulation. Its advantages are primarily reflected in the following aspects:

First, precise coverage of high-temperature areas. The integrated water channels create an "annular cooling belt" around each combustion chamber and provide multiple layers of surrounding water jackets around the exhaust valve seats, ensuring adequate cooling of areas most susceptible to overheating. Some high-performance engines even feature micro-cooling channels near the spark plug ceramic body to directly reduce the temperature in the ignition zone, suppressing pre-ignition and knock.

Secondly, they optimize coolant flow characteristics. By designing variable-section flow channels, guide fins, and vortex structures, integrated water channels control coolant flow rate and direction, avoiding localized stagnation or excessive turbulence. For example, flow rate is appropriately reduced on the intake side to minimize heat loss, while flow rate is increased on the exhaust side to enhance heat dissipation. Furthermore, a rational inlet and outlet layout ensures coolant flows from low-temperature areas to high-temperature areas, achieving "countercurrent heat exchange" and improving heat exchange efficiency.

Third, they improve overall thermal uniformity. Integrated water channels evenly distribute coolant flow, significantly reducing temperature differences across different areas of the cylinder head. Experimental data shows that cylinder heads with optimized integrated water channels can reduce the maximum surface temperature difference from over 80°C in conventional designs to less than 40°C, significantly reducing the risk of thermal stress concentration and extending component life.

3. Collaborative Advances in Materials and Manufacturing Processes

The integrated water channel design relies on advanced casting processes, such as precision sand casting or high-pressure die casting, to ensure the precision of the complex flow channels. Furthermore, the use of high-strength aluminum alloy ensures that the cylinder head reduces weight while maintaining excellent thermal conductivity and thermal fatigue resistance, further enhancing cooling effectiveness.

In summary, the integrated water channel design of the cylinder head represents not only a structural improvement but also an innovation in thermal management concepts. Through the scientific layout of cooling channels and precise control of heat flow distribution, it significantly optimizes cooling efficiency and effectively reduces the formation of hot spots, providing a solid foundation for high engine efficiency, reliability, and long life.

1. Limitations of Traditional Cooling Design

In early engine designs, cylinder head cooling channels were often simply drilled or cast, resulting in a crude layout, uneven coolant flow paths, and insufficient flow rate control. Especially in high-temperature areas such as those around the combustion chamber, exhaust valve seats, and spark plugs, the complex structure and wide variations in wall thickness make it difficult for coolant to adequately cover them. This leads to heat accumulation and the formation of localized high-temperature zones. This uneven cooling not only reduces the fatigue life of the material but can also cause cylinder head warping, compromise the seal between the cylinder block and head, and cause serious failures such as "head gasket blowout."

2. Core Advantages of Integrated Water Channel Design

Integrated water channel design involves embedding coolant channels three-dimensionally into the cylinder head structure using precision molds during the casting process. This creates a complex network of flow channels that surround the combustion chamber, penetrate the valve seats, and proximate the exhaust ports. This design goes beyond simple "through-holes" to create a highly efficient cooling system optimized through CFD simulation. Its advantages are primarily reflected in the following aspects:

First, precise coverage of high-temperature areas. The integrated water channels create an "annular cooling belt" around each combustion chamber and provide multiple layers of surrounding water jackets around the exhaust valve seats, ensuring adequate cooling of areas most susceptible to overheating. Some high-performance engines even feature micro-cooling channels near the spark plug ceramic body to directly reduce the temperature in the ignition zone, suppressing pre-ignition and knock.

Secondly, they optimize coolant flow characteristics. By designing variable-section flow channels, guide fins, and vortex structures, integrated water channels control coolant flow rate and direction, avoiding localized stagnation or excessive turbulence. For example, flow rate is appropriately reduced on the intake side to minimize heat loss, while flow rate is increased on the exhaust side to enhance heat dissipation. Furthermore, a rational inlet and outlet layout ensures coolant flows from low-temperature areas to high-temperature areas, achieving "countercurrent heat exchange" and improving heat exchange efficiency.

Third, they improve overall thermal uniformity. Integrated water channels evenly distribute coolant flow, significantly reducing temperature differences across different areas of the cylinder head. Experimental data shows that cylinder heads with optimized integrated water channels can reduce the maximum surface temperature difference from over 80°C in conventional designs to less than 40°C, significantly reducing the risk of thermal stress concentration and extending component life.

3. Collaborative Advances in Materials and Manufacturing Processes

The integrated water channel design relies on advanced casting processes, such as precision sand casting or high-pressure die casting, to ensure the precision of the complex flow channels. Furthermore, the use of high-strength aluminum alloy ensures that the cylinder head reduces weight while maintaining excellent thermal conductivity and thermal fatigue resistance, further enhancing cooling effectiveness.

In summary, the integrated water channel design of the cylinder head represents not only a structural improvement but also an innovation in thermal management concepts. Through the scientific layout of cooling channels and precise control of heat flow distribution, it significantly optimizes cooling efficiency and effectively reduces the formation of hot spots, providing a solid foundation for high engine efficiency, reliability, and long life.