How does the cylinder head improve overall engine performance and efficiency?

Release Time : 2025-08-12

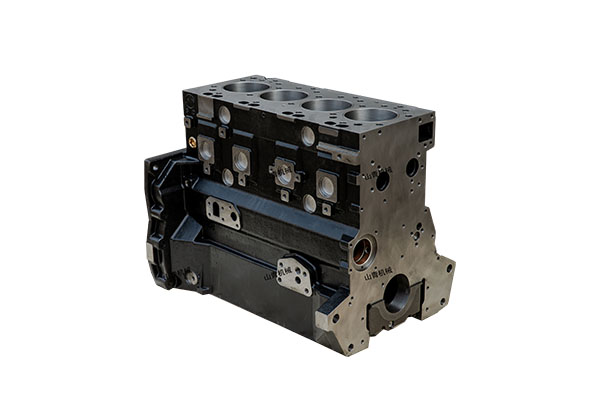

The cylinder head plays a vital role in improving overall engine performance and efficiency. As a core component of the internal combustion engine, the cylinder head not only directly impacts the efficiency of the combustion process but also has a profound impact on engine cooling, intake and exhaust, and overall structural strength. By utilizing advanced materials, optimized design, and precision manufacturing processes, modern cylinder heads can significantly improve engine power output, fuel economy, and durability.

First, the design of the cylinder head is crucial to optimizing the combustion process. The combustion chamber is where the fuel and air mix and ignite, and its shape and volume directly influence combustion efficiency. Modern cylinder heads typically feature a compact combustion chamber design to minimize heat loss and ensure complete combustion of the fuel under optimal conditions. This design not only improves combustion efficiency, reduces unburned fuel, but also reduces emissions. Furthermore, some high-performance cylinder heads incorporate specialized intake duct designs that optimize airflow paths, promote more uniform mixture distribution, and further enhance combustion.

Second, the material choice of the cylinder head significantly impacts its performance. To withstand high-temperature and high-pressure operating environments, modern cylinder heads are typically constructed from high-strength aluminum alloy or cast iron. Aluminum alloy's excellent thermal conductivity helps quickly dissipate heat generated during combustion, thereby maintaining an ideal engine temperature. Furthermore, aluminum alloy's lightweight construction reduces vehicle weight, thereby improving acceleration and fuel economy. Cast iron, on the other hand, is renowned for its exceptional wear and pressure resistance, making it particularly suitable for heavy-duty engines operating under high loads.

Furthermore, the complex cooling channel design within the cylinder head is a key factor in enhancing engine performance. An effective cooling system quickly dissipates the substantial heat generated during combustion, preventing localized overheating that could lead to component damage or deformation. Many modern cylinder heads utilize advanced cooling channel layouts, such as cross-flow or spiral flow designs, which achieve more uniform cooling and ensure adequate heat dissipation across all components. Furthermore, some high-end cylinder heads feature active cooling technologies, such as variable-flow water pumps or intelligent temperature control systems, that dynamically adjust coolant flow based on actual operating conditions to further optimize heat dissipation.

It's worth noting that the sealing performance of the cylinder head is directly related to engine reliability and durability. High-quality cylinder head gaskets and precise machining ensure a tight fit between the cylinder head and the cylinder block, preventing oil and coolant from leaking into the combustion chamber. Furthermore, good sealing effectively prevents the escape of high-pressure gases within the combustion chamber, maintaining a normal compression ratio, which is crucial for ensuring engine power output. Even the slightest leak can lead to reduced power, increased fuel consumption, or even serious mechanical failure. Therefore, stringent sealing requirements are a key criterion for cylinder head quality.

In addition, the multifunctional integrated design of the cylinder head simplifies the overall engine structure, improving system integration and reliability. In addition to the traditional combustion chamber and cooling channels, modern cylinder heads often integrate key components such as the intake and exhaust manifolds, and the camshaft. This integrated design not only saves space and reduces weight, but also reduces potential errors in assembly and improves production efficiency. Especially for turbocharged engines, integrated cylinder heads can better coordinate the intake and exhaust processes, fully utilizing exhaust gas energy to drive the turbocharger, significantly improving engine output and response speed.

Finally, with the advancement of intelligent technology, future cylinder heads are expected to integrate more intelligent functions, further enhancing engine performance. For example, embedded sensors can monitor the cylinder head's operating status in real time, including parameters such as temperature, pressure, and vibration, and feed this information back to the central control system. Once an anomaly is detected, the system immediately takes appropriate measures to prevent the fault from escalating. This proactive management approach not only improves equipment safety but also provides users with a more convenient operating experience. Furthermore, with the integration of IoT technology, multiple cylinder heads can be interconnected to form an efficient monitoring network, optimizing resource allocation and improving overall operational efficiency.

In summary, the cylinder head, through its optimized combustion chamber design, advanced material selection, complex cooling channel layout, excellent sealing performance, multifunctional integrated design, and potential intelligent applications, plays a vital role in improving overall engine performance and efficiency. Each improvement is designed to provide a better user experience and demonstrates a deep understanding and respect for user needs and social responsibility. In the future, as new materials and technologies continue to emerge, cylinder heads will demonstrate their unique value in even more areas, propelling the entire industry to new heights. Both emerging and established industries can benefit from this, working together to create more efficient, reliable, and environmentally friendly power solutions.

First, the design of the cylinder head is crucial to optimizing the combustion process. The combustion chamber is where the fuel and air mix and ignite, and its shape and volume directly influence combustion efficiency. Modern cylinder heads typically feature a compact combustion chamber design to minimize heat loss and ensure complete combustion of the fuel under optimal conditions. This design not only improves combustion efficiency, reduces unburned fuel, but also reduces emissions. Furthermore, some high-performance cylinder heads incorporate specialized intake duct designs that optimize airflow paths, promote more uniform mixture distribution, and further enhance combustion.

Second, the material choice of the cylinder head significantly impacts its performance. To withstand high-temperature and high-pressure operating environments, modern cylinder heads are typically constructed from high-strength aluminum alloy or cast iron. Aluminum alloy's excellent thermal conductivity helps quickly dissipate heat generated during combustion, thereby maintaining an ideal engine temperature. Furthermore, aluminum alloy's lightweight construction reduces vehicle weight, thereby improving acceleration and fuel economy. Cast iron, on the other hand, is renowned for its exceptional wear and pressure resistance, making it particularly suitable for heavy-duty engines operating under high loads.

Furthermore, the complex cooling channel design within the cylinder head is a key factor in enhancing engine performance. An effective cooling system quickly dissipates the substantial heat generated during combustion, preventing localized overheating that could lead to component damage or deformation. Many modern cylinder heads utilize advanced cooling channel layouts, such as cross-flow or spiral flow designs, which achieve more uniform cooling and ensure adequate heat dissipation across all components. Furthermore, some high-end cylinder heads feature active cooling technologies, such as variable-flow water pumps or intelligent temperature control systems, that dynamically adjust coolant flow based on actual operating conditions to further optimize heat dissipation.

It's worth noting that the sealing performance of the cylinder head is directly related to engine reliability and durability. High-quality cylinder head gaskets and precise machining ensure a tight fit between the cylinder head and the cylinder block, preventing oil and coolant from leaking into the combustion chamber. Furthermore, good sealing effectively prevents the escape of high-pressure gases within the combustion chamber, maintaining a normal compression ratio, which is crucial for ensuring engine power output. Even the slightest leak can lead to reduced power, increased fuel consumption, or even serious mechanical failure. Therefore, stringent sealing requirements are a key criterion for cylinder head quality.

In addition, the multifunctional integrated design of the cylinder head simplifies the overall engine structure, improving system integration and reliability. In addition to the traditional combustion chamber and cooling channels, modern cylinder heads often integrate key components such as the intake and exhaust manifolds, and the camshaft. This integrated design not only saves space and reduces weight, but also reduces potential errors in assembly and improves production efficiency. Especially for turbocharged engines, integrated cylinder heads can better coordinate the intake and exhaust processes, fully utilizing exhaust gas energy to drive the turbocharger, significantly improving engine output and response speed.

Finally, with the advancement of intelligent technology, future cylinder heads are expected to integrate more intelligent functions, further enhancing engine performance. For example, embedded sensors can monitor the cylinder head's operating status in real time, including parameters such as temperature, pressure, and vibration, and feed this information back to the central control system. Once an anomaly is detected, the system immediately takes appropriate measures to prevent the fault from escalating. This proactive management approach not only improves equipment safety but also provides users with a more convenient operating experience. Furthermore, with the integration of IoT technology, multiple cylinder heads can be interconnected to form an efficient monitoring network, optimizing resource allocation and improving overall operational efficiency.

In summary, the cylinder head, through its optimized combustion chamber design, advanced material selection, complex cooling channel layout, excellent sealing performance, multifunctional integrated design, and potential intelligent applications, plays a vital role in improving overall engine performance and efficiency. Each improvement is designed to provide a better user experience and demonstrates a deep understanding and respect for user needs and social responsibility. In the future, as new materials and technologies continue to emerge, cylinder heads will demonstrate their unique value in even more areas, propelling the entire industry to new heights. Both emerging and established industries can benefit from this, working together to create more efficient, reliable, and environmentally friendly power solutions.