Why are cylinder blocks so important to crankshaft stability?

Release Time : 2025-07-29

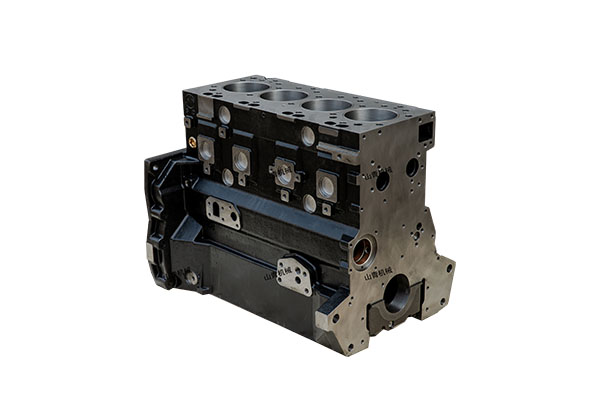

During the working process of the engine, cylinder blocks are not only the basic structure that supports and fixes key components such as pistons and connecting rods, but also play a vital role in the stability and reliability of the entire power system. Especially for the crankshaft, the design and manufacturing quality of cylinder blocks directly affect its running smoothness and durability.

1. Cylinder blocks as the "skeleton" of the engine

Cylinder blocks are usually made of high-strength materials such as cast iron or aluminum alloy. It not only provides a closed space for piston movement, but also serves as the installation basis for all moving parts inside the engine. Among them, the main bearing seat is one of the most critical parts of the cylinder blocks. It is the main support point when the crankshaft rotates. The design and processing accuracy of the main bearing seat directly determines whether the crankshaft can run smoothly on its predetermined track. Since the engine will generate huge mechanical and thermal stresses when it is working, if the cylinder blocks are not strong enough or there are manufacturing defects, it may cause the crankshaft to deviate or vibrate more, which will affect the overall performance of the engine and even cause serious damage.

2. Importance of main bearing seat design

The main bearing seats are usually located at the bottom of the cylinder blocks. They are bolted to the cylinder blocks and form a series of fixed pivots around the crankshaft. These pivots not only have to withstand the pressure from the combustion chamber, but also have to deal with the centrifugal force and inertia force generated when the crankshaft rotates at high speed. Therefore, the main bearing seats must have sufficient rigidity and strength to ensure that the crankshaft can remain stable under high load conditions. To achieve this goal, modern engines usually adopt a multi-point support design concept and set main bearing seats at multiple locations to disperse the load. In addition, some high-performance engines will add additional reinforcement ribs or use more advanced casting processes (such as sand casting, low-pressure casting, etc.) to improve the overall rigidity of the cylinder blocks and reduce the risk of deformation.

3. Precise processing and assembly requirements

In addition to reasonable structural design, the processing accuracy of cylinder blocks cannot be ignored. Especially in terms of the main bearing seat aperture size and its coaxiality, any slight deviation may cause the crankshaft to run unsteadily, leading to abnormal noise, vibration and even increased wear. Therefore, during the production process, manufacturers often use high-precision CNC machine tools for processing, and cooperate with equipment such as three-coordinate measuring instruments to strictly control the tolerance range. In addition, the assembly link is also crucial. The correct application of preload and the selection of lubrication conditions will affect the final operating effect. For example, when installing the main bearing cap, it is necessary to gradually tighten the bolts in the prescribed order and torque value to avoid deformation caused by uneven local force.

4. The role of the cooling system

A good cooling system is also one of the key factors to ensure the stability of the crankshaft. When the engine is working, a lot of heat will be generated. If the heat is not dissipated in time, the temperature in the cylinder blocks will be too high, causing thermal expansion. This uneven expansion may change the relative position between the main bearing seats, causing the crankshaft to deviate from the normal trajectory. For this reason, many engines use a water cooling system to remove excess heat through circulating coolant to maintain a balanced distribution of temperatures in various parts of the cylinder blocks. Some high-performance models are also equipped with independent oil cooling devices to further reduce the operating temperature of key components and extend their service life.

5. Fault diagnosis and maintenance

When abnormal vibration or other suspected crankshaft instability is found in the engine, the cylinder blocks should be checked for cracks, deformation and other problems first. Common detection methods include ultrasonic flaw detection, magnetic particle flaw detection and visual inspection. Once a problem is found, the damaged parts should be repaired or replaced in time to avoid greater losses. In daily maintenance work, it is also necessary to regularly check the lubricating oil status, cleanliness and effectiveness of the cooling system. This helps to detect potential hidden dangers in advance and ensure that the cylinder blocks are always in the best working condition.

In summary, cylinder blocks are not only an important part of the engine, but also an indispensable foundation for ensuring the stable operation of the crankshaft. From structural design to processing accuracy, to the improvement of the cooling system, every link needs to be carefully considered and implemented to ensure that the crankshaft can still operate smoothly and efficiently under complex working conditions. With the advancement of technology, we are expected to see more innovative designs applied to the cylinder blocks manufacturing field in the future, opening up new ways to improve the overall performance of the engine.

1. Cylinder blocks as the "skeleton" of the engine

Cylinder blocks are usually made of high-strength materials such as cast iron or aluminum alloy. It not only provides a closed space for piston movement, but also serves as the installation basis for all moving parts inside the engine. Among them, the main bearing seat is one of the most critical parts of the cylinder blocks. It is the main support point when the crankshaft rotates. The design and processing accuracy of the main bearing seat directly determines whether the crankshaft can run smoothly on its predetermined track. Since the engine will generate huge mechanical and thermal stresses when it is working, if the cylinder blocks are not strong enough or there are manufacturing defects, it may cause the crankshaft to deviate or vibrate more, which will affect the overall performance of the engine and even cause serious damage.

2. Importance of main bearing seat design

The main bearing seats are usually located at the bottom of the cylinder blocks. They are bolted to the cylinder blocks and form a series of fixed pivots around the crankshaft. These pivots not only have to withstand the pressure from the combustion chamber, but also have to deal with the centrifugal force and inertia force generated when the crankshaft rotates at high speed. Therefore, the main bearing seats must have sufficient rigidity and strength to ensure that the crankshaft can remain stable under high load conditions. To achieve this goal, modern engines usually adopt a multi-point support design concept and set main bearing seats at multiple locations to disperse the load. In addition, some high-performance engines will add additional reinforcement ribs or use more advanced casting processes (such as sand casting, low-pressure casting, etc.) to improve the overall rigidity of the cylinder blocks and reduce the risk of deformation.

3. Precise processing and assembly requirements

In addition to reasonable structural design, the processing accuracy of cylinder blocks cannot be ignored. Especially in terms of the main bearing seat aperture size and its coaxiality, any slight deviation may cause the crankshaft to run unsteadily, leading to abnormal noise, vibration and even increased wear. Therefore, during the production process, manufacturers often use high-precision CNC machine tools for processing, and cooperate with equipment such as three-coordinate measuring instruments to strictly control the tolerance range. In addition, the assembly link is also crucial. The correct application of preload and the selection of lubrication conditions will affect the final operating effect. For example, when installing the main bearing cap, it is necessary to gradually tighten the bolts in the prescribed order and torque value to avoid deformation caused by uneven local force.

4. The role of the cooling system

A good cooling system is also one of the key factors to ensure the stability of the crankshaft. When the engine is working, a lot of heat will be generated. If the heat is not dissipated in time, the temperature in the cylinder blocks will be too high, causing thermal expansion. This uneven expansion may change the relative position between the main bearing seats, causing the crankshaft to deviate from the normal trajectory. For this reason, many engines use a water cooling system to remove excess heat through circulating coolant to maintain a balanced distribution of temperatures in various parts of the cylinder blocks. Some high-performance models are also equipped with independent oil cooling devices to further reduce the operating temperature of key components and extend their service life.

5. Fault diagnosis and maintenance

When abnormal vibration or other suspected crankshaft instability is found in the engine, the cylinder blocks should be checked for cracks, deformation and other problems first. Common detection methods include ultrasonic flaw detection, magnetic particle flaw detection and visual inspection. Once a problem is found, the damaged parts should be repaired or replaced in time to avoid greater losses. In daily maintenance work, it is also necessary to regularly check the lubricating oil status, cleanliness and effectiveness of the cooling system. This helps to detect potential hidden dangers in advance and ensure that the cylinder blocks are always in the best working condition.

In summary, cylinder blocks are not only an important part of the engine, but also an indispensable foundation for ensuring the stable operation of the crankshaft. From structural design to processing accuracy, to the improvement of the cooling system, every link needs to be carefully considered and implemented to ensure that the crankshaft can still operate smoothly and efficiently under complex working conditions. With the advancement of technology, we are expected to see more innovative designs applied to the cylinder blocks manufacturing field in the future, opening up new ways to improve the overall performance of the engine.