How does cummins 2.8 cylinder blocks improve the overall efficiency of the engine through optimized design?

Release Time : 2025-07-16

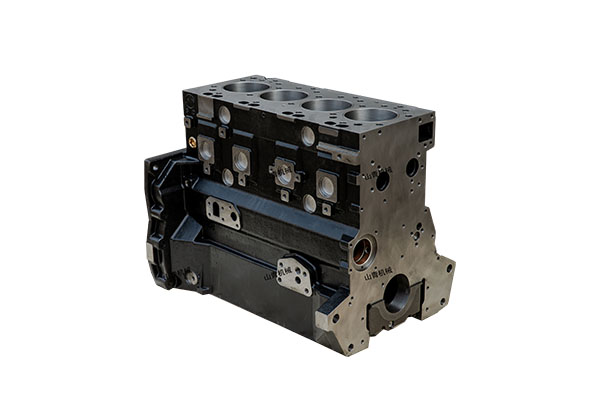

As one of the core components of the engine, cummins 2.8 cylinder blocks carry the important mission of converting the energy generated by fuel combustion into mechanical power. This precision-made cylinder block not only reflects the high integration and optimized design of modern internal combustion engine technology, but also sets an industry benchmark in terms of durability, efficiency and reliability. It is widely used in light commercial vehicles, construction machinery and agricultural machinery, and has won the trust of global users with its excellent performance.

First of all, from the perspective of structural design, cummins 2.8 cylinder blocks adopt advanced casting technology to ensure the complexity and precision of the internal structure of the cylinder block. The application of high-strength cast iron material makes the cylinder block have excellent tensile strength and wear resistance, and can withstand the pressure shock caused by long-term high-load operation. In addition, the carefully designed cooling water channel layout effectively improves the heat dissipation efficiency and prevents the occurrence of local overheating, which is crucial to maintaining stable engine operation. Under extreme working conditions, such as high temperature or high altitude areas, this efficient heat dissipation system can significantly extend the engine life and improve overall work efficiency.

Secondly, the design of cummins 2.8 cylinder blocks takes full account of the modular concept. This means that different models of engines can meet specific application requirements by adjusting some components without changing the basic architecture. For example, in light commercial vehicles, the cylinder block can achieve different configurations from economical to high-performance by matching different key components such as pistons, connecting rods and crankshafts, so as to adapt to diverse market needs. At the same time, the modular design also simplifies the maintenance process and reduces user maintenance costs. When a component has a problem, only the corresponding module needs to be replaced, without large-scale disassembly of the entire engine, which greatly saves time and money.

Furthermore, cummins 2.8 cylinder blocks also have outstanding performance in environmental protection and energy saving. With the increasingly stringent global environmental regulations, reducing emissions has become a common challenge faced by all engine manufacturers. To this end, Cummins has incorporated a series of innovative technologies into its 2.8 cylinder block design, such as optimizing the shape of the combustion chamber to improve fuel injection efficiency, using advanced exhaust gas recirculation (EGR) systems to reduce NOx emissions, and using high-pressure common rail fuel injection systems for precise control. These measures not only help reduce harmful emissions, but also improve fuel economy, so that vehicles can meet environmental protection requirements while also bringing lower operating costs to users.

In addition, cummins 2.8 cylinder blocks also focus on user experience and intelligent development. Modern engines are increasingly integrated with electronic control systems, which can dynamically adjust the engine's operating status through real-time monitoring and analysis of sensor data. For example, the intelligent throttle response system can automatically adjust the engine output power according to driving habits; the fault diagnosis system can warn of potential problems in advance, helping car owners to take timely measures to avoid greater losses. These intelligent functions have greatly enhanced the market competitiveness of the product and also improved user satisfaction.

Finally, the strong R&D capabilities and perfect after-sales service network behind the Cummins brand are also one of the reasons why its 2.8 cylinder blocks are favored by customers. With years of accumulated technical experience and continuous R&D investment, Cummins has always been at the forefront of technological innovation and continuously launched new products that meet the needs of the times. At the same time, service outlets around the world provide users with all-round support, whether it is parts supply or technical guidance, they can get a quick response to ensure that every engine equipped with cummins 2.8 cylinder blocks can maintain optimal operation.

Cummins 2.8 cylinder blocks are not just a simple mechanical component, but also a product that integrates advanced design concepts, exquisite manufacturing technology and considerate service experience. It supports the power source of the engine with a solid structure and leads the development trend of the industry with a spirit of continuous innovation.

First of all, from the perspective of structural design, cummins 2.8 cylinder blocks adopt advanced casting technology to ensure the complexity and precision of the internal structure of the cylinder block. The application of high-strength cast iron material makes the cylinder block have excellent tensile strength and wear resistance, and can withstand the pressure shock caused by long-term high-load operation. In addition, the carefully designed cooling water channel layout effectively improves the heat dissipation efficiency and prevents the occurrence of local overheating, which is crucial to maintaining stable engine operation. Under extreme working conditions, such as high temperature or high altitude areas, this efficient heat dissipation system can significantly extend the engine life and improve overall work efficiency.

Secondly, the design of cummins 2.8 cylinder blocks takes full account of the modular concept. This means that different models of engines can meet specific application requirements by adjusting some components without changing the basic architecture. For example, in light commercial vehicles, the cylinder block can achieve different configurations from economical to high-performance by matching different key components such as pistons, connecting rods and crankshafts, so as to adapt to diverse market needs. At the same time, the modular design also simplifies the maintenance process and reduces user maintenance costs. When a component has a problem, only the corresponding module needs to be replaced, without large-scale disassembly of the entire engine, which greatly saves time and money.

Furthermore, cummins 2.8 cylinder blocks also have outstanding performance in environmental protection and energy saving. With the increasingly stringent global environmental regulations, reducing emissions has become a common challenge faced by all engine manufacturers. To this end, Cummins has incorporated a series of innovative technologies into its 2.8 cylinder block design, such as optimizing the shape of the combustion chamber to improve fuel injection efficiency, using advanced exhaust gas recirculation (EGR) systems to reduce NOx emissions, and using high-pressure common rail fuel injection systems for precise control. These measures not only help reduce harmful emissions, but also improve fuel economy, so that vehicles can meet environmental protection requirements while also bringing lower operating costs to users.

In addition, cummins 2.8 cylinder blocks also focus on user experience and intelligent development. Modern engines are increasingly integrated with electronic control systems, which can dynamically adjust the engine's operating status through real-time monitoring and analysis of sensor data. For example, the intelligent throttle response system can automatically adjust the engine output power according to driving habits; the fault diagnosis system can warn of potential problems in advance, helping car owners to take timely measures to avoid greater losses. These intelligent functions have greatly enhanced the market competitiveness of the product and also improved user satisfaction.

Finally, the strong R&D capabilities and perfect after-sales service network behind the Cummins brand are also one of the reasons why its 2.8 cylinder blocks are favored by customers. With years of accumulated technical experience and continuous R&D investment, Cummins has always been at the forefront of technological innovation and continuously launched new products that meet the needs of the times. At the same time, service outlets around the world provide users with all-round support, whether it is parts supply or technical guidance, they can get a quick response to ensure that every engine equipped with cummins 2.8 cylinder blocks can maintain optimal operation.

Cummins 2.8 cylinder blocks are not just a simple mechanical component, but also a product that integrates advanced design concepts, exquisite manufacturing technology and considerate service experience. It supports the power source of the engine with a solid structure and leads the development trend of the industry with a spirit of continuous innovation.