How does the cylinder head optimize airflow efficiency?

Release Time : 2025-10-22

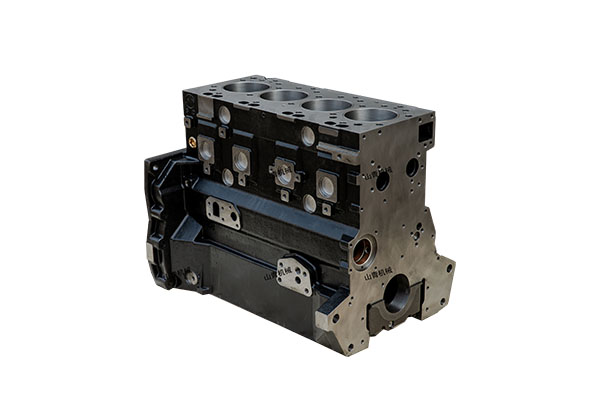

In the operation of an internal combustion engine, the cylinder head is not only a critical structural component that encloses the combustion chamber but also serves as the central hub for controlling intake and exhaust flow. Its internal design directly determines how smoothly the engine "breathes," which in turn affects combustion efficiency, power output, and emissions performance. The cylinder head is, in a sense, the "command center" for efficient airflow management in the engine.

1. Streamlined Intake and Exhaust Ports: Reducing Flow Resistance

One of the most critical components within the cylinder head is the intake and exhaust ports, which act as the engine's "breathing passages." To enhance airflow efficiency, modern cylinder heads utilize streamlined, smooth-walled intake and exhaust ports, mimicking aerodynamic principles to reduce turbulence, separation, and friction losses. Engineers use CFD simulations to continuously optimize the port's cross-sectional shape, curvature angles, and gradient transitions to ensure stable air or mixture flow at high speeds and maximize intake volume. Especially at high engine speeds, well-designed intake ports significantly improve volumetric efficiency, allowing more fresh air to enter the cylinders and creating conditions for efficient combustion.

2. Multi-Valve Structure: Improving Airflow Capacity

Traditional engines often use a two-valve per cylinder design, but this structure limits the airflow area. Modern high-performance engines generally adopt three, four, or even five-valve designs per cylinder, with the "dual-inlet, dual-row" four-valve structure being the most common. This multi-valve layout significantly increases the total valve opening area, ensuring fuller intake and more complete exhaust. Furthermore, multiple small-diameter valves are lighter and have lower inertia than a single large-diameter valve, making them more suitable for high-rpm operation. This requires a more complex cylinder head design with valve seats, guides, and actuation mechanisms, but the trade-off is significantly improved airflow efficiency and engine responsiveness.

3. Optimizing Combustion Chamber Shape and Valve Angle: Enhancing Tumble and Turbulence

The shape of the combustion chamber at the bottom of the cylinder head has a profound impact on airflow patterns. Designers adjust the combustion chamber's concave profile, spark plug position, and intake and exhaust valve angles to guide the intake air into forming a tumble or swirl upon entering the cylinder. These organized airflow movements accelerate the mixing of air and fuel, improve combustion speed and stability, and reduce incomplete combustion and emissions. For example, some high-efficiency engines utilize "high-tumble combustion chambers." These use angled intake ports and narrow-angle valve arrangements to create strong vertical tumble during the compression stroke, improving combustion efficiency and supporting lean burn and high compression ratio technologies.

4. Variable Valve Technology Integration: Dynamic Airflow Adjustment

The cylinder head also integrates variable valve timing and variable valve lift systems. These technologies use hydraulically controlled phase adjusters or variable rocker mechanisms to adjust valve opening timing and lift height in real time, ensuring optimal airflow matching at varying engine speeds and loads. For example, they delay intake valve closing at low speeds to increase torque, while advancing valve opening at high speeds to enhance intake efficiency. These complex mechanisms, embedded within or on top of the cylinder head, reflect the evolution of modern cylinder heads from static structures to intelligently controlled systems.

5. Cooling and Structural Design: Ensuring Stable Airflow System Operation

Efficient airflow management requires a stable thermal environment. The cylinder head features complex cooling channels arranged around the combustion chamber and exhaust ducts, effectively dissipating high-temperature heat and preventing localized overheating that could lead to valve deformation or detonation. Furthermore, the rigidity and sealing properties of the cylinder head are crucial. Only by maintaining deformation under high temperatures and pressures can the valves and seats fit tightly together, preventing air leaks and maintaining the integrity of the airflow system.

The cylinder head comprehensively improves engine airflow efficiency through a combination of optimized intake and exhaust ducts, a multi-valve layout, combustion chamber design, variable valve technology, and thermal management. It is not just a combination of mechanical structure but also the culmination of aerodynamics, materials science, and precision manufacturing. As engines evolve towards higher efficiency and lower emissions, the cylinder head's airflow optimization technology will continue to play a key role in improving both power and environmental performance.

1. Streamlined Intake and Exhaust Ports: Reducing Flow Resistance

One of the most critical components within the cylinder head is the intake and exhaust ports, which act as the engine's "breathing passages." To enhance airflow efficiency, modern cylinder heads utilize streamlined, smooth-walled intake and exhaust ports, mimicking aerodynamic principles to reduce turbulence, separation, and friction losses. Engineers use CFD simulations to continuously optimize the port's cross-sectional shape, curvature angles, and gradient transitions to ensure stable air or mixture flow at high speeds and maximize intake volume. Especially at high engine speeds, well-designed intake ports significantly improve volumetric efficiency, allowing more fresh air to enter the cylinders and creating conditions for efficient combustion.

2. Multi-Valve Structure: Improving Airflow Capacity

Traditional engines often use a two-valve per cylinder design, but this structure limits the airflow area. Modern high-performance engines generally adopt three, four, or even five-valve designs per cylinder, with the "dual-inlet, dual-row" four-valve structure being the most common. This multi-valve layout significantly increases the total valve opening area, ensuring fuller intake and more complete exhaust. Furthermore, multiple small-diameter valves are lighter and have lower inertia than a single large-diameter valve, making them more suitable for high-rpm operation. This requires a more complex cylinder head design with valve seats, guides, and actuation mechanisms, but the trade-off is significantly improved airflow efficiency and engine responsiveness.

3. Optimizing Combustion Chamber Shape and Valve Angle: Enhancing Tumble and Turbulence

The shape of the combustion chamber at the bottom of the cylinder head has a profound impact on airflow patterns. Designers adjust the combustion chamber's concave profile, spark plug position, and intake and exhaust valve angles to guide the intake air into forming a tumble or swirl upon entering the cylinder. These organized airflow movements accelerate the mixing of air and fuel, improve combustion speed and stability, and reduce incomplete combustion and emissions. For example, some high-efficiency engines utilize "high-tumble combustion chambers." These use angled intake ports and narrow-angle valve arrangements to create strong vertical tumble during the compression stroke, improving combustion efficiency and supporting lean burn and high compression ratio technologies.

4. Variable Valve Technology Integration: Dynamic Airflow Adjustment

The cylinder head also integrates variable valve timing and variable valve lift systems. These technologies use hydraulically controlled phase adjusters or variable rocker mechanisms to adjust valve opening timing and lift height in real time, ensuring optimal airflow matching at varying engine speeds and loads. For example, they delay intake valve closing at low speeds to increase torque, while advancing valve opening at high speeds to enhance intake efficiency. These complex mechanisms, embedded within or on top of the cylinder head, reflect the evolution of modern cylinder heads from static structures to intelligently controlled systems.

5. Cooling and Structural Design: Ensuring Stable Airflow System Operation

Efficient airflow management requires a stable thermal environment. The cylinder head features complex cooling channels arranged around the combustion chamber and exhaust ducts, effectively dissipating high-temperature heat and preventing localized overheating that could lead to valve deformation or detonation. Furthermore, the rigidity and sealing properties of the cylinder head are crucial. Only by maintaining deformation under high temperatures and pressures can the valves and seats fit tightly together, preventing air leaks and maintaining the integrity of the airflow system.

The cylinder head comprehensively improves engine airflow efficiency through a combination of optimized intake and exhaust ducts, a multi-valve layout, combustion chamber design, variable valve technology, and thermal management. It is not just a combination of mechanical structure but also the culmination of aerodynamics, materials science, and precision manufacturing. As engines evolve towards higher efficiency and lower emissions, the cylinder head's airflow optimization technology will continue to play a key role in improving both power and environmental performance.