How does the integrated casting design of cylinder blocks improve engine rigidity and operational stability?

Release Time : 2025-10-10

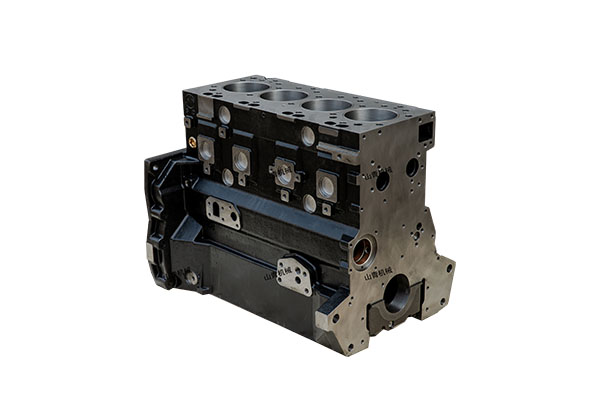

In the design and manufacturing of modern automotive engines, cylinder blocks are core structural components whose performance directly determines overall engine reliability, power output efficiency, and operating smoothness. With the continuous advancement of manufacturing technology, integrated casting has gradually replaced traditional split or spliced structures, becoming the preferred manufacturing process for cylinder blocks in mainstream engines. This integrated casting design not only improves production efficiency but also offers significant advantages in engine rigidity and operational stability.

1. Improving Overall Structural Rigidity and Reducing Deformation

Cylinder blocks are subjected to complex mechanical and thermal loads during engine operation. High-pressure gases generated by combustion, the impact of piston reciprocating motion, and high temperatures all exert continuous stress on the cylinder blocks. Traditional split-body structures often use bolts to connect multiple components, and these joints are prone to stress concentration points. After long-term use, slight displacement or loosening may occur, leading to a decrease in structural rigidity. The integrated casting design eliminates seams and connectors by casting key components such as the cylinder barrel, main bearing housing, water channels, and oil channels in a single process, making the entire cylinder block a continuous, uniform metal structure. This structure significantly improves the overall rigidity of the cylinder blocks, effectively suppresses deformation under high-pressure and high-heat conditions, and ensures precise alignment of all moving parts within the engine.

2. Optimizing Stress Distribution and Enhancing Fatigue Strength

During the engine operating cycle, the internal stress distribution within the cylinder blocks is complex and dynamically changing. The integrated casting design allows engineers to optimize the structure through finite element analysis during the design phase, optimally arranging ribs, wall thickness, and transition radius to ensure uniform stress distribution throughout the entire structure and avoid localized stress concentrations. Furthermore, the continuity of the metal material during the casting process ensures a dense and consistent internal structure, reducing defects such as porosity and inclusions, thereby improving the material's fatigue strength. This optimized stress distribution and material properties ensure that the cylinder blocks maintain structural stability under long-term, high-load operation, extending the engine's service life.

3. Improved Assembly Precision, Ensuring Smooth Operation

Smooth engine operation relies on the high-precision fit between various components. The motion paths of moving parts such as the crankshaft, connecting rod, and piston must be strictly controlled; even the slightest deviation can cause vibration and noise. The integrally cast cylinder blocks ensure high consistency in key dimensions, such as the main bearing bore, cylinder centerline, and oil channel location. The main bearing seat is formed as a single unit, eliminating the need for bolted assembly. This ensures the coaxiality and parallelism of the crankshaft mounting bore, significantly reducing crankshaft runout and friction during operation. Furthermore, the cylinder bores are machined using a uniform datum, minimizing dimensional tolerances between cylinders. This ensures more synchronized piston movement within each cylinder, reducing unbalanced forces caused by assembly errors and significantly improving engine operation smoothness.

4. Enhanced Vibration Resistance, Reduced Noise

Engine operation generates inherent vibration, which is particularly prominent under high speed or high load conditions. The integrally cast cylinder blocks, with their high structural rigidity and even mass distribution, offer improved dynamic response. It more effectively absorbs and dissipates vibration energy, reducing resonance. Furthermore, the integrated structure reduces friction and impact noise caused by relative motion between components, thus reducing mechanical noise at the source. This is crucial for improving the vehicle's NVH (noise, vibration, and harshness) performance, providing a quieter and more comfortable experience for drivers and passengers.

In summary, the integrated casting design of the cylinder blocks enhances the engine's mechanical stability and operating smoothness by increasing structural rigidity, optimizing stress distribution, improving assembly precision, and enhancing vibration resistance. It is not only the technological foundation for the development of modern engines that are lightweight and efficient, but also a key support for achieving high performance, long life, and low noise.

1. Improving Overall Structural Rigidity and Reducing Deformation

Cylinder blocks are subjected to complex mechanical and thermal loads during engine operation. High-pressure gases generated by combustion, the impact of piston reciprocating motion, and high temperatures all exert continuous stress on the cylinder blocks. Traditional split-body structures often use bolts to connect multiple components, and these joints are prone to stress concentration points. After long-term use, slight displacement or loosening may occur, leading to a decrease in structural rigidity. The integrated casting design eliminates seams and connectors by casting key components such as the cylinder barrel, main bearing housing, water channels, and oil channels in a single process, making the entire cylinder block a continuous, uniform metal structure. This structure significantly improves the overall rigidity of the cylinder blocks, effectively suppresses deformation under high-pressure and high-heat conditions, and ensures precise alignment of all moving parts within the engine.

2. Optimizing Stress Distribution and Enhancing Fatigue Strength

During the engine operating cycle, the internal stress distribution within the cylinder blocks is complex and dynamically changing. The integrated casting design allows engineers to optimize the structure through finite element analysis during the design phase, optimally arranging ribs, wall thickness, and transition radius to ensure uniform stress distribution throughout the entire structure and avoid localized stress concentrations. Furthermore, the continuity of the metal material during the casting process ensures a dense and consistent internal structure, reducing defects such as porosity and inclusions, thereby improving the material's fatigue strength. This optimized stress distribution and material properties ensure that the cylinder blocks maintain structural stability under long-term, high-load operation, extending the engine's service life.

3. Improved Assembly Precision, Ensuring Smooth Operation

Smooth engine operation relies on the high-precision fit between various components. The motion paths of moving parts such as the crankshaft, connecting rod, and piston must be strictly controlled; even the slightest deviation can cause vibration and noise. The integrally cast cylinder blocks ensure high consistency in key dimensions, such as the main bearing bore, cylinder centerline, and oil channel location. The main bearing seat is formed as a single unit, eliminating the need for bolted assembly. This ensures the coaxiality and parallelism of the crankshaft mounting bore, significantly reducing crankshaft runout and friction during operation. Furthermore, the cylinder bores are machined using a uniform datum, minimizing dimensional tolerances between cylinders. This ensures more synchronized piston movement within each cylinder, reducing unbalanced forces caused by assembly errors and significantly improving engine operation smoothness.

4. Enhanced Vibration Resistance, Reduced Noise

Engine operation generates inherent vibration, which is particularly prominent under high speed or high load conditions. The integrally cast cylinder blocks, with their high structural rigidity and even mass distribution, offer improved dynamic response. It more effectively absorbs and dissipates vibration energy, reducing resonance. Furthermore, the integrated structure reduces friction and impact noise caused by relative motion between components, thus reducing mechanical noise at the source. This is crucial for improving the vehicle's NVH (noise, vibration, and harshness) performance, providing a quieter and more comfortable experience for drivers and passengers.

In summary, the integrated casting design of the cylinder blocks enhances the engine's mechanical stability and operating smoothness by increasing structural rigidity, optimizing stress distribution, improving assembly precision, and enhancing vibration resistance. It is not only the technological foundation for the development of modern engines that are lightweight and efficient, but also a key support for achieving high performance, long life, and low noise.