How does the cylinder head cooling system achieve efficient heat dissipation?

Release Time : 2025-05-22

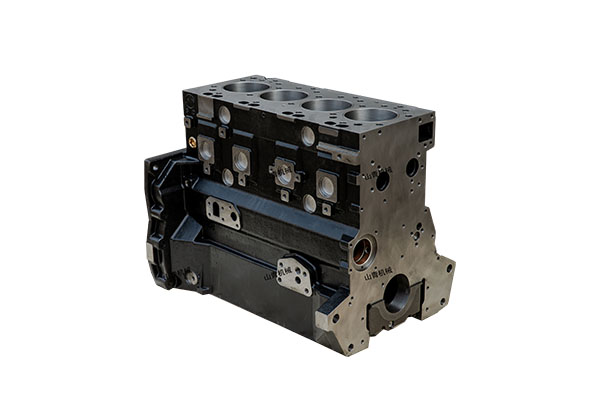

The cooling system of the cylinder head is one of the core links of the engine thermal management. Its efficient heat dissipation capacity directly affects the power output, reliability and service life of the engine. Since the working environment of the cylinder head is extreme - it must withstand the frequent impact of high-temperature gas and ensure the precise working temperature of key components such as valves, spark plugs (or injectors), the cooling system needs to build a comprehensive heat dissipation system through scientific structural design, reasonable medium circulation and intelligent control strategy.

Is the basis for achieving efficient heat dissipation. Modern engine cylinder heads are usually designed with complex water jacket structures. These water jackets wrap high-heat areas such as combustion chambers, valve seats and injector holes in a three-dimensional form. For example, a narrow slit water jacket design in the "nose bridge area" is used around the combustion chamber to reduce the cross-sectional area of the coolant flow channel and increase the flow rate to enhance convective heat transfer; a surrounding cooling groove is set near the valve seat ring to carry out directional heat dissipation for the local high temperature generated by the frequent opening and closing of the valve. Some high-performance engines also embed guide plates or spoiler ribs in the water jacket to guide the coolant to form turbulence, destroy the laminar boundary layer close to the metal wall, and improve the heat dissipation efficiency by more than 30%.

Determines the efficiency of heat transfer. The cooling system usually adopts a forced circulation mode, and the water pump provides power to push the coolant to circulate between the cylinder head water jacket and the radiator. When the engine is cold started, the thermostat closes the large circulation path, and the coolant only circulates in the cylinder head, quickly heating up to reduce wear; after reaching the operating temperature, the thermostat opens, and the high-temperature coolant flows into the radiator, and the temperature is reduced by forced air cooling through the fan. Some advanced systems also introduce electronic water pumps and variable displacement technology. According to the cylinder head temperature data monitored in real time by the ECU, the coolant flow rate is dynamically adjusted to avoid thermal efficiency loss caused by overcooling, while ensuring that the high heat load area is always in the best heat dissipation state.

Provide support for heat dissipation performance. The cylinder head body is mostly made of aluminum alloy with excellent thermal conductivity, and its thermal conductivity is 3-5 times that of cast iron, which can quickly transfer heat to the coolant. For engines in extreme working conditions such as racing cars, copper alloys or ceramic-based composite materials are even used to make local high-heat areas. The surface treatment of the inner wall of the water jacket is also crucial. The rough microporous structure formed by the electrochemical corrosion process can increase the contact area between the coolant and the metal; some manufacturers also use nano-coating technology to reduce the surface tension of the liquid, so that the coolant can cover the wall more evenly and reduce the heat dissipation failure caused by cavitation.

Further optimize the heat dissipation performance. Modern engines are generally equipped with a temperature sensor network to monitor the temperature data of different areas of the cylinder head in real time. When the temperature of a certain area exceeds the threshold, the ECU will instruct the electronic fan to increase the speed, increase the radiator air volume, or turn on an independent auxiliary water pump to increase the local coolant flow rate. In turbocharged engines, a special turbocharger cooling circuit is also set up to preheat the turbine lubricating oil through the waste heat of the cylinder head water jacket, while avoiding overheating of the turbine body. This collaborative design of thermal management improves the overall heat dissipation efficiency by about 20%. In addition, some hybrid models use an integrated electric heating and cooling system, which uses the residual heat of the motor to heat the coolant at low temperatures and quickly switches to the cooling mode at high temperatures to achieve efficient use of energy.

Expanded the cooling boundary. The cooling structure outside the cylinder head is no longer limited to the internal water jacket, but is combined with the overall aerodynamic design of the engine compartment. For example, a guide groove is designed on the surface of the cylinder head cover to guide the high-speed airflow through the top of the cylinder head and take away some heat through forced convection; in a V-type engine, the angle between the two rows of cylinder heads is used to form a "wind gathering groove", which is combined with the angle optimization of the radiator grille to increase the air flow through the cooling system by 15%-20%. This composite cooling mode that combines internal liquid cooling with external air cooling is particularly suitable for engines with high power density.

Ensure long-term and reliable operation of the cooling system. Check the coolant level and freezing point regularly to avoid a decrease in heat dissipation capacity due to evaporation or chemical reaction; pay attention to whether there are signs of coolant leakage at the water jacket interface. Once found, the seal gasket needs to be replaced or the cracks need to be repaired in time. When the engine overheats, it is necessary to check whether the thermostat is stuck, whether the water pump impeller is worn, and whether the cooling fan control module is faulty. For old models that use hard water as coolant, it is also necessary to be vigilant about the problem of scale deposition in the water jacket. Chemical cleaning can be used to remove the scale and restore the cross-sectional area of the water jacket to avoid deformation or cracks in the cylinder head due to poor local heat dissipation.

With the development trend of engine miniaturization and high power, the cylinder head cooling system is evolving in the direction of "precision, intelligence, and lightweight". In the future, 3D printing technology will promote the popularization of more complex special-shaped water jackets, allowing coolant to reach dead corners that cannot be processed by traditional processes; the application of electronic coolant pumps and solid-state temperature control valves will achieve millisecond-level precise control of coolant flow; and coolants based on new materials such as graphene have a thermal conductivity several times higher than that of traditional ethylene glycol solutions, which is expected to completely revolutionize the engine heat dissipation mode. These technological breakthroughs will continue to improve the heat dissipation limit of the cylinder head and lay the foundation for further leaps in engine performance.