How to improve the core components of the cummins 2.8 cylinder head engine performance?

Release Time : 2025-05-09

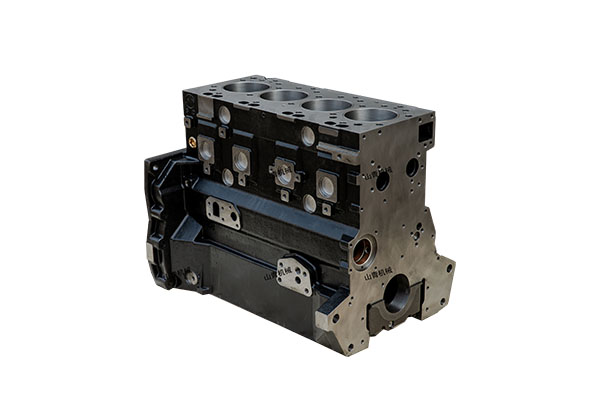

Among the many key components of a diesel engine, the cylinder head plays a vital role. Especially for a high-efficiency engine like the Cummins 2.8, the design and manufacturing quality of its cylinder head directly affects the overall performance, fuel economy and reliability of the engine. So, what are the characteristics of the cummins 2.8 cylinder head? How does it bring significant improvements to the engine?

First of all, the cummins 2.8 cylinder head uses advanced materials and precision manufacturing processes. In order to cope with the working conditions of high compression ratio and high temperature environment, Cummins uses high-strength aluminum alloy or cast iron as the main material, which not only ensures the structural strength of the cylinder head, but also effectively reduces the overall weight and improves the efficiency of the engine. At the same time, through precision casting and CNC machining technology, it ensures that every detail meets extremely high precision requirements, thereby achieving the best sealing effect and thermal management performance.

Secondly, the design of the cummins 2.8 cylinder head focuses on optimizing the shape of the combustion chamber and the layout of the intake and exhaust valves. The optimized combustion chamber can promote the full mixing of fuel and air, improve combustion efficiency, and thus increase power output and reduce emissions. In addition, the reasonable intake and exhaust valve arrangement helps to enhance gas flow, reduce pumping losses, and further improve the engine's working efficiency. Some models are also equipped with a variable valve timing (VVT) system, which automatically adjusts the time of valve opening and closing according to different working conditions to achieve better power response and smoothness.

In addition, the cummins 2.8 cylinder head integrates cooling channels, which is essential for maintaining the normal operating temperature of the engine. An efficient cooling system can prevent local overheating, extend engine life, and maintain stable performance. These cooling channels are usually cleverly designed inside the cylinder head to ensure that the coolant can be evenly distributed to various key areas and effectively remove heat.

In addition to the above-mentioned technical features, the cummins 2.8 cylinder head also pays special attention to durability and maintenance convenience. For example, during the design process, the wear and tear in daily use is fully considered, and wear-resistant coatings or special treatment processes are used to enhance surface hardness and reduce friction losses. In addition, the modular design makes maintenance easier and faster. Some parts can be replaced directly without disassembling the entire cylinder head, which greatly reduces the maintenance cost and time.

From the perspective of practical application, the Cummins 2.8 cylinder head is widely used in light commercial vehicles, agricultural machinery and small industrial equipment. With its excellent performance and reliability, this engine has won a good reputation worldwide. Whether it is long-distance transportation or heavy-duty operation, the Cummins 2.8 engine can provide strong power support and excellent fuel economy to meet the needs of various complex working conditions.

In short, the Cummins 2.8 cylinder head is not only an important part of the engine, but also one of the key factors that determine its performance. By adopting advanced materials, optimizing design and integrating multiple innovative technologies, the cylinder head has successfully improved the overall efficiency of the engine, achieving higher power output, lower emission levels and longer service life. With the continuous advancement and development of technology, it is believed that the future Cummins engine will continue to lead the industry trend and provide users with more outstanding products and services. For those users who pursue high performance and high reliability, choosing an engine equipped with a Cummins 2.8 cylinder head is undoubtedly a wise choice.

First of all, the cummins 2.8 cylinder head uses advanced materials and precision manufacturing processes. In order to cope with the working conditions of high compression ratio and high temperature environment, Cummins uses high-strength aluminum alloy or cast iron as the main material, which not only ensures the structural strength of the cylinder head, but also effectively reduces the overall weight and improves the efficiency of the engine. At the same time, through precision casting and CNC machining technology, it ensures that every detail meets extremely high precision requirements, thereby achieving the best sealing effect and thermal management performance.

Secondly, the design of the cummins 2.8 cylinder head focuses on optimizing the shape of the combustion chamber and the layout of the intake and exhaust valves. The optimized combustion chamber can promote the full mixing of fuel and air, improve combustion efficiency, and thus increase power output and reduce emissions. In addition, the reasonable intake and exhaust valve arrangement helps to enhance gas flow, reduce pumping losses, and further improve the engine's working efficiency. Some models are also equipped with a variable valve timing (VVT) system, which automatically adjusts the time of valve opening and closing according to different working conditions to achieve better power response and smoothness.

In addition, the cummins 2.8 cylinder head integrates cooling channels, which is essential for maintaining the normal operating temperature of the engine. An efficient cooling system can prevent local overheating, extend engine life, and maintain stable performance. These cooling channels are usually cleverly designed inside the cylinder head to ensure that the coolant can be evenly distributed to various key areas and effectively remove heat.

In addition to the above-mentioned technical features, the cummins 2.8 cylinder head also pays special attention to durability and maintenance convenience. For example, during the design process, the wear and tear in daily use is fully considered, and wear-resistant coatings or special treatment processes are used to enhance surface hardness and reduce friction losses. In addition, the modular design makes maintenance easier and faster. Some parts can be replaced directly without disassembling the entire cylinder head, which greatly reduces the maintenance cost and time.

From the perspective of practical application, the Cummins 2.8 cylinder head is widely used in light commercial vehicles, agricultural machinery and small industrial equipment. With its excellent performance and reliability, this engine has won a good reputation worldwide. Whether it is long-distance transportation or heavy-duty operation, the Cummins 2.8 engine can provide strong power support and excellent fuel economy to meet the needs of various complex working conditions.

In short, the Cummins 2.8 cylinder head is not only an important part of the engine, but also one of the key factors that determine its performance. By adopting advanced materials, optimizing design and integrating multiple innovative technologies, the cylinder head has successfully improved the overall efficiency of the engine, achieving higher power output, lower emission levels and longer service life. With the continuous advancement and development of technology, it is believed that the future Cummins engine will continue to lead the industry trend and provide users with more outstanding products and services. For those users who pursue high performance and high reliability, choosing an engine equipped with a Cummins 2.8 cylinder head is undoubtedly a wise choice.