What are the main materials and performance advantages of cummins 3.8 cylinder blocks?

Release Time : 2025-06-18

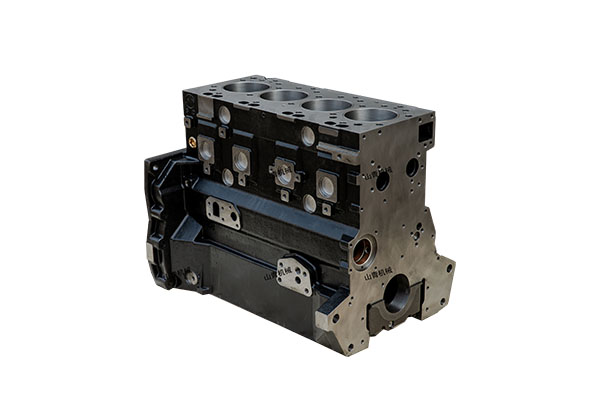

In the field of modern diesel engine manufacturing, cummins 3.8 cylinder blocks, as a key component in the power system, bear the core function of engine operation. It is not only the installation basis of important components such as cylinders, pistons, crankshafts, but also directly determines the overall strength, durability and working stability of the engine. As a power platform widely used in light commercial vehicles, construction machinery and agricultural machinery, Cummins 3.8L engine is deeply recognized by the market for its reliability and high efficiency, and its cylinder block plays an irreplaceable role in it.

The cylinder block is the "skeleton" of the engine. Its main function is to support and accommodate the various moving parts inside the engine and withstand high temperature and high pressure working environment. Cummins 3.8 cylinder blocks are cast with high-strength cast iron or aluminum alloy, with good thermal stability and fatigue resistance, and can maintain structural integrity under long-term high-load operation. This material selection not only improves the wear resistance and heat dissipation capacity of the cylinder block, but also effectively reduces the vibration and noise during the operation of the engine, and improves the overall comfort of use.

From the perspective of structural design, the cummins 3.8 cylinder blocks adopts an optimized layout of water and oil channel systems to ensure that the coolant and lubricating oil can circulate efficiently and maintain the engine running within the optimal temperature range. In addition, there are multiple reinforcing ribs and support structures inside the cylinder block to enhance the overall rigidity and prevent deformation caused by pressure fluctuations. Such a design helps to extend the life of the engine, especially for working conditions with frequent start-stop and large load changes.

In terms of assembly compatibility, the cummins 3.8 cylinder blocks have highly standardized design features, which are easy to repair and replace. Whether it is original assembly or later overhaul, this type of cylinder block can be well matched with various pistons, connecting rods, crankshafts and other key components, providing great convenience for users. At the same time, due to its mature technical system and wide market application, the supply of related accessories is sufficient and the maintenance cost is relatively low, which further enhances its cost-effectiveness advantage.

It is worth mentioning that with the increasingly stringent emission standards, the cummins 3.8 cylinder blocks are also constantly upgrading their technology. For example, honing technology is introduced in the inner wall processing technology of the cylinder body to improve the surface finish and sealing performance; the combustion chamber structure is optimized to improve fuel efficiency and reduce harmful gas emissions. These improvements enable the engine equipped with this cylinder block to maintain strong power output and stable operating performance while meeting environmental protection requirements.

In addition, cummins 3.8 cylinder blocks are also widely used in the field of modification and performance tuning. Many vehicle enthusiasts and professional technicians tap the potential of the engine by strengthening, expanding the cylinder or matching high-performance pistons and camshafts to obtain stronger power output and longer durability. This not only reflects the good plasticity of the cylinder block, but also illustrates its forward-looking engineering design.

As the core component of the diesel engine, cummins 3.8 cylinder blocks have shown excellent performance in a variety of application scenarios with their solid structural design, excellent material properties, and excellent adaptability and maintainability. Whether in urban distribution, rural transportation, or engineering machinery operations, it provides a solid guarantee for the stable operation of the engine. In the future, with the development of green power and intelligent control technology, this classic cylinder block will continue to play an important role in continuous innovation.

The cylinder block is the "skeleton" of the engine. Its main function is to support and accommodate the various moving parts inside the engine and withstand high temperature and high pressure working environment. Cummins 3.8 cylinder blocks are cast with high-strength cast iron or aluminum alloy, with good thermal stability and fatigue resistance, and can maintain structural integrity under long-term high-load operation. This material selection not only improves the wear resistance and heat dissipation capacity of the cylinder block, but also effectively reduces the vibration and noise during the operation of the engine, and improves the overall comfort of use.

From the perspective of structural design, the cummins 3.8 cylinder blocks adopts an optimized layout of water and oil channel systems to ensure that the coolant and lubricating oil can circulate efficiently and maintain the engine running within the optimal temperature range. In addition, there are multiple reinforcing ribs and support structures inside the cylinder block to enhance the overall rigidity and prevent deformation caused by pressure fluctuations. Such a design helps to extend the life of the engine, especially for working conditions with frequent start-stop and large load changes.

In terms of assembly compatibility, the cummins 3.8 cylinder blocks have highly standardized design features, which are easy to repair and replace. Whether it is original assembly or later overhaul, this type of cylinder block can be well matched with various pistons, connecting rods, crankshafts and other key components, providing great convenience for users. At the same time, due to its mature technical system and wide market application, the supply of related accessories is sufficient and the maintenance cost is relatively low, which further enhances its cost-effectiveness advantage.

It is worth mentioning that with the increasingly stringent emission standards, the cummins 3.8 cylinder blocks are also constantly upgrading their technology. For example, honing technology is introduced in the inner wall processing technology of the cylinder body to improve the surface finish and sealing performance; the combustion chamber structure is optimized to improve fuel efficiency and reduce harmful gas emissions. These improvements enable the engine equipped with this cylinder block to maintain strong power output and stable operating performance while meeting environmental protection requirements.

In addition, cummins 3.8 cylinder blocks are also widely used in the field of modification and performance tuning. Many vehicle enthusiasts and professional technicians tap the potential of the engine by strengthening, expanding the cylinder or matching high-performance pistons and camshafts to obtain stronger power output and longer durability. This not only reflects the good plasticity of the cylinder block, but also illustrates its forward-looking engineering design.

As the core component of the diesel engine, cummins 3.8 cylinder blocks have shown excellent performance in a variety of application scenarios with their solid structural design, excellent material properties, and excellent adaptability and maintainability. Whether in urban distribution, rural transportation, or engineering machinery operations, it provides a solid guarantee for the stable operation of the engine. In the future, with the development of green power and intelligent control technology, this classic cylinder block will continue to play an important role in continuous innovation.